- Home

- Services / Solutions

- PalletWorks Integrated Packaging

Eliminate End-of-Line Rework with PalletWorks Production Labeling Software

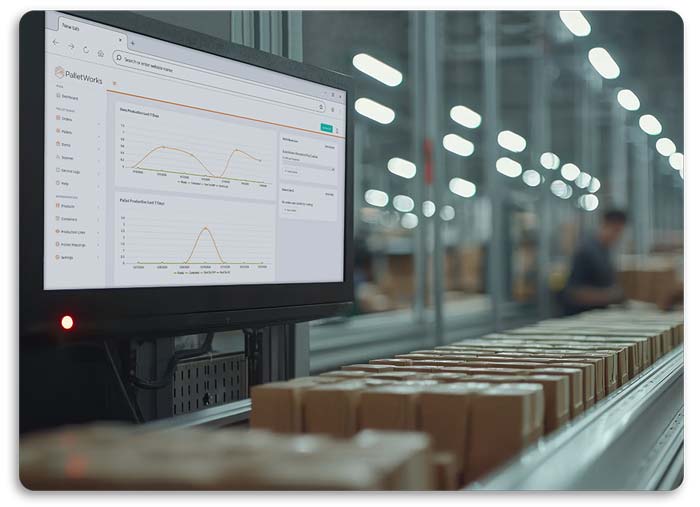

PalletWorks is a fully integrated tracking and labeling software solution that helps manufacturers automate end-of-line tasks to eliminate rework due to human error. PalletWorks is a subscription-based SaaS platform that intelligently bridges the gap between the manufacturing floor and the ERP system. With the PalletWorks web portal, operators can mass edit and reprint labels before sending the information to the ERP, resulting in better product tracking, inventory accuracy, and fulfillment efficiency.

PalletWorks: A Software Solution that Automates End-of-Line Tasks to Eliminate End-of-Line Rework

PalletWorks software not only integrates with packaging and labeling hardware on the plant floor, but also communicates with existing controls and ERP systems. This unrivaled and complete integration makes PalletWorks an ideal solution for increasing production accuracy and simplifying tasks at the end of the line, all through a single vendor.

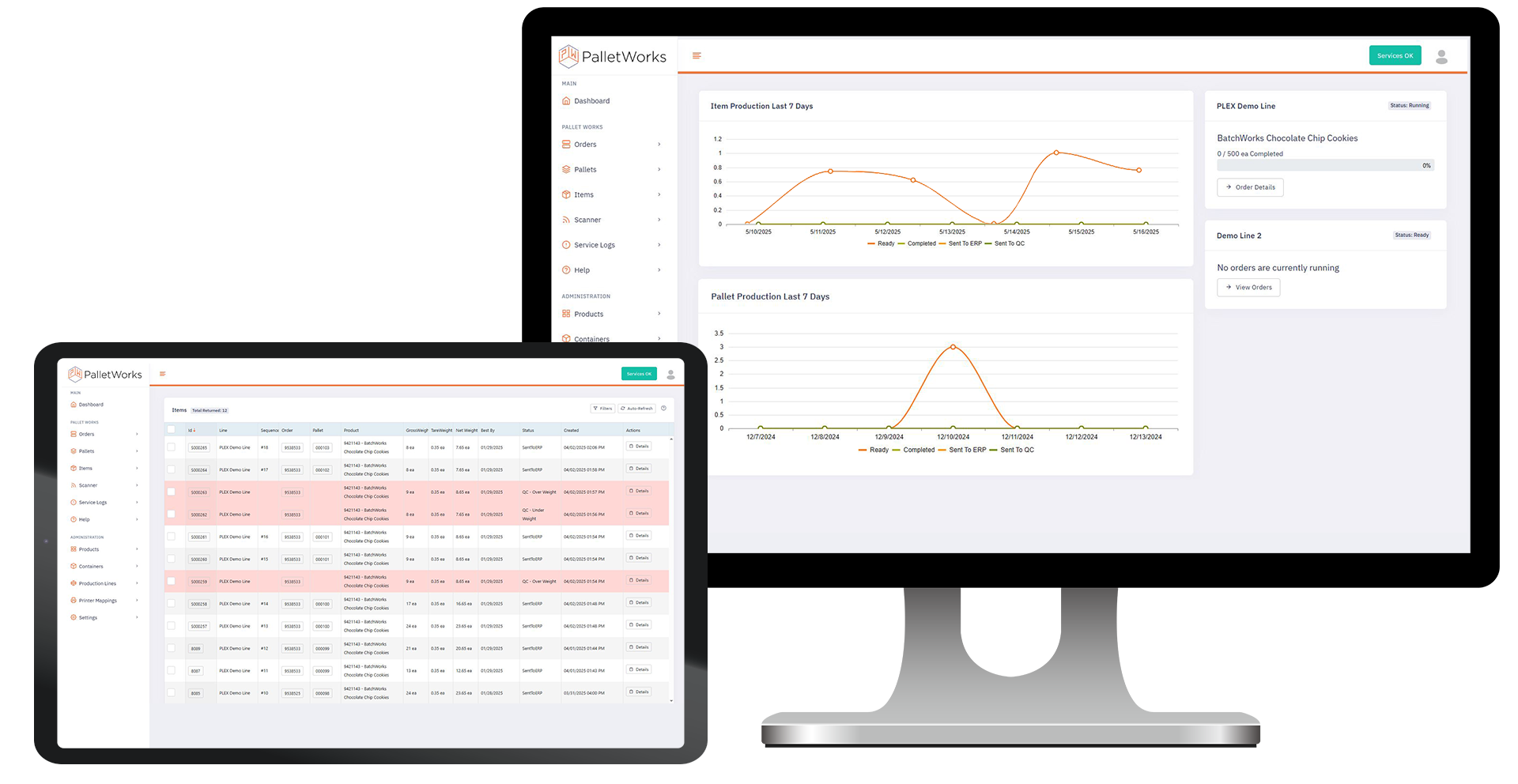

PalletWorks includes everything required for an enterprise-level tracking and labeling solution. PalletWorks software continuously monitors throughput, labels cases and pallets, records production data, and can be seamlessly integrated with the ERP system for real-time updates. In addition to its automated features, it also allows operators the flexibility of bulk editing and label reprints before data transfer to the ERP or other business systems.

PalletWorks Quote Request

Features and Benefits

- Records, tracks, and labels cases and pallets

- Allows bulk editing and label reprints before data transfer to the ERP

- Provides a configurable and operator-friendly web-based portal, accessible from industrial tablets on the floor as well as back-office PCs

- Leverages HMI screens to highlight hardware statuses

- Integrates into any modern control system or manufacturing environment

- Cybertrol Engineering offers 24/7/365 support for PalletWorks, including remote monitoring, diagnostics, and troubleshooting

Empower your Factory Floor Associates with the PalletWorks Web Portal

The PalletWorks (PW) web-based portal is the primary means of operation and is designed to be used on an industrial tablet and/or traditional PC. The software collects, tracks, and records data throughout the labeling process. Operators can review and edit the data in the PalletWorks portal, ensuring accurate information is sent to ERP or other business systems (through API integration).

- User interface can be configured to use terms familiar to your organization

- Data can be visible or hidden to focus an operator's attention

- Production workflows can be customized with configuration options

- Integration triggers with the ERP can be set and automated

Reduce the Risk of Human Error by Automating Tasks

For many manufacturers, every step at the end-of-the-line has some sort of manual process with multiple people involved. This level of human interaction often leads to unintentional errors when printing and applying labels. PalletWorks is a fully-integrated solution designed to help manufacturers reduce human error and automate end-of-line tasks.

Integration with PLEX, by Rockwell Automation

As a PLEX, by Rockwell Automation Service Partner, Cybertrol Engineering can not only offer the best in Smart Manufacturing Solutions, but we have also integrated our PalletWorks solution with the PLEX, by Rockwell Automation manufacturing execution suite (MES) platform. This seamless integration can benefit manufacturers by providing real-time insights, data-driven decision-making, and improved control over production lines.

An Auditor for Your End-of-line Tasks

- Continuously records and validates production data in real-time

- Collects an inventory of items on a pallet

- Communicates with ERP systems for seamless data flow

- Generates feedback reports on production output

- Ensures labels are accurate, properly applied, and can be machine scanned

- Manages order fulfillment during production runs

- Identifies production errors as they occur on the line

- Allows operators to edit data before it's sent to the ERP

PalletWorks Testimonial

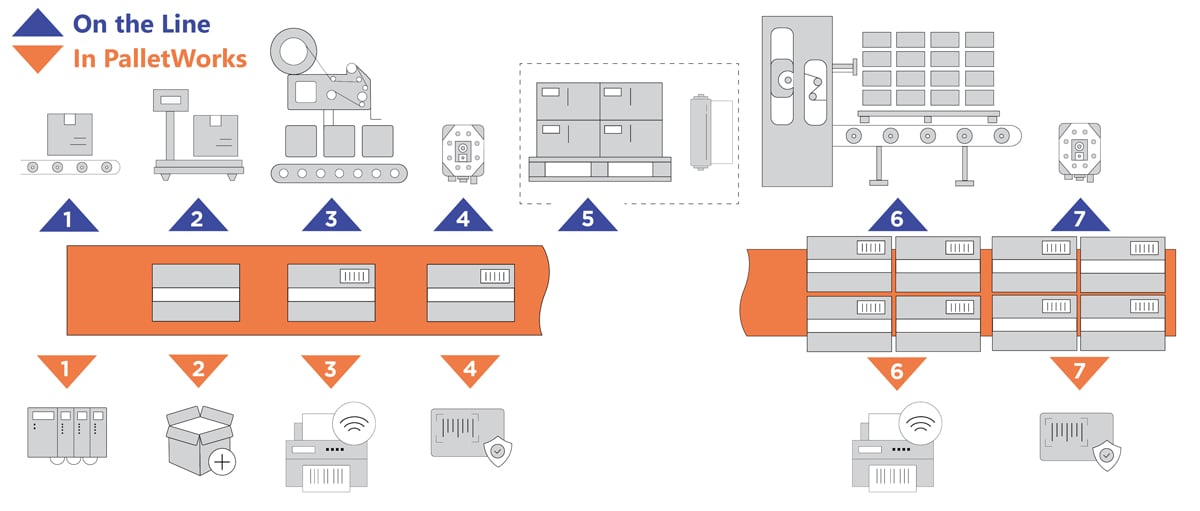

PalletWorks on the Production Line

What's happening on the production line?

- Order is active on production line

- Item is created (i.e. Scale)

- Printer/applicator applies item label

- Industrial scanner scans item label

- Pallet is stacked and shrink-wrapped

- Printer/applicator applies pallet label

- Industrial scanner scans pallet label

What's happening in PalletWorks (PW)?

- Set active order in PW portal (PLC integration/manual entry)

- PW receives signal from PLC that an item is created

- PW sends request to print item label

- PW waits for item label to be scanned to identify any errors

- PW creates a digital STACK of the pallet

- PW sends request to print pallet label

- PW waits for pallet label to be scanned to identify any errors

PalletWorks integrates with your ERP system to coordinate packaging line configuration and report finished goods production.

- Support for both on-premise and cloud-hosted ERP systems

- Orders from ERP readily available for selection at each packaging line

- Product validation ensures correct product is used to fulfill orders

- Flexible product identification schemes accommodate existing labeling requirements

- Validated production seamlessly reported to ERP and/or WMS systems

- Manual pallet creation capability minimizes inventory discrepancies and empowers staff

PalletWorks was created with self-sufficiency and maintenance in mind. It is not a “black box” solution, and is easily configured, maintained, and even expanded upon by local engineering resources. Much of PalletWorks’ power comes from it’s presence at the controls level, allowing it to integrate directly with other equipment in the packaging process including printers, conveyors, palletizers, pallet wrappers, and AGV systems. The programming for PalletWorks is completely open, making it efficient to troubleshoot and tailor to your exact requirements.

While PalletWorks can be provided a turnkey solution including printing, scanning, labeling, and operator interface hardware, it can also be retrofitted into existing infrastructure and is platform agnostic. We have existing templates for a number of HMI platforms and support dozens of printer manufacturers including:

- Rockwell Automation

- WonderWare

- Inductive Automation

- Zebra

- VideoJet

- SATO

- Domino

- Markem-Imaje

Download our Whitepaper: Optimizing Packaging Operations with PalletWorks.

Download