Scope Creep Starts Earlier Than You Think: A System ...

Why early automation and OT decisions shape cost, schedule, and long-term performance in food and beverage capital projects Scope creep is one of the most common challenges in ...

Cybertrol Engineering is a control and information systems integrator focused on optimizing industrial manufacturing. We specialize in plantwide automation, IT/OT convergence, MES implementation, and real-time manufacturing intelligence—backed by responsive 24/7 support. Our solutions are built to scale, adapt, and perform.

End-to-end process control and information solutions, PLC/HMI programming, project management, infrastructure modernization, batch control, and more to streamline the way your factory operates.

With accurate and timely data capture, a manufacturing execution system (MES) allows you to monitor and control manufacturing activities, ensuring adherence to schedules, minimizing downtime, and maximizing throughput.

We're there when you need us with 24/7/365 support. We have a dedicated support team of career engineers that are ready to answer your questions about automation, servers, and industrial networks.

Industries We Serve

Optimized manufacturing with knowledge-driven, secure operations.

Achieve product integrity with consistent validation, tracking, and traceability.

Master complex manufacturing processes with zero disruptions.

PMO compliant process control solutions to keep operations running smoothly.

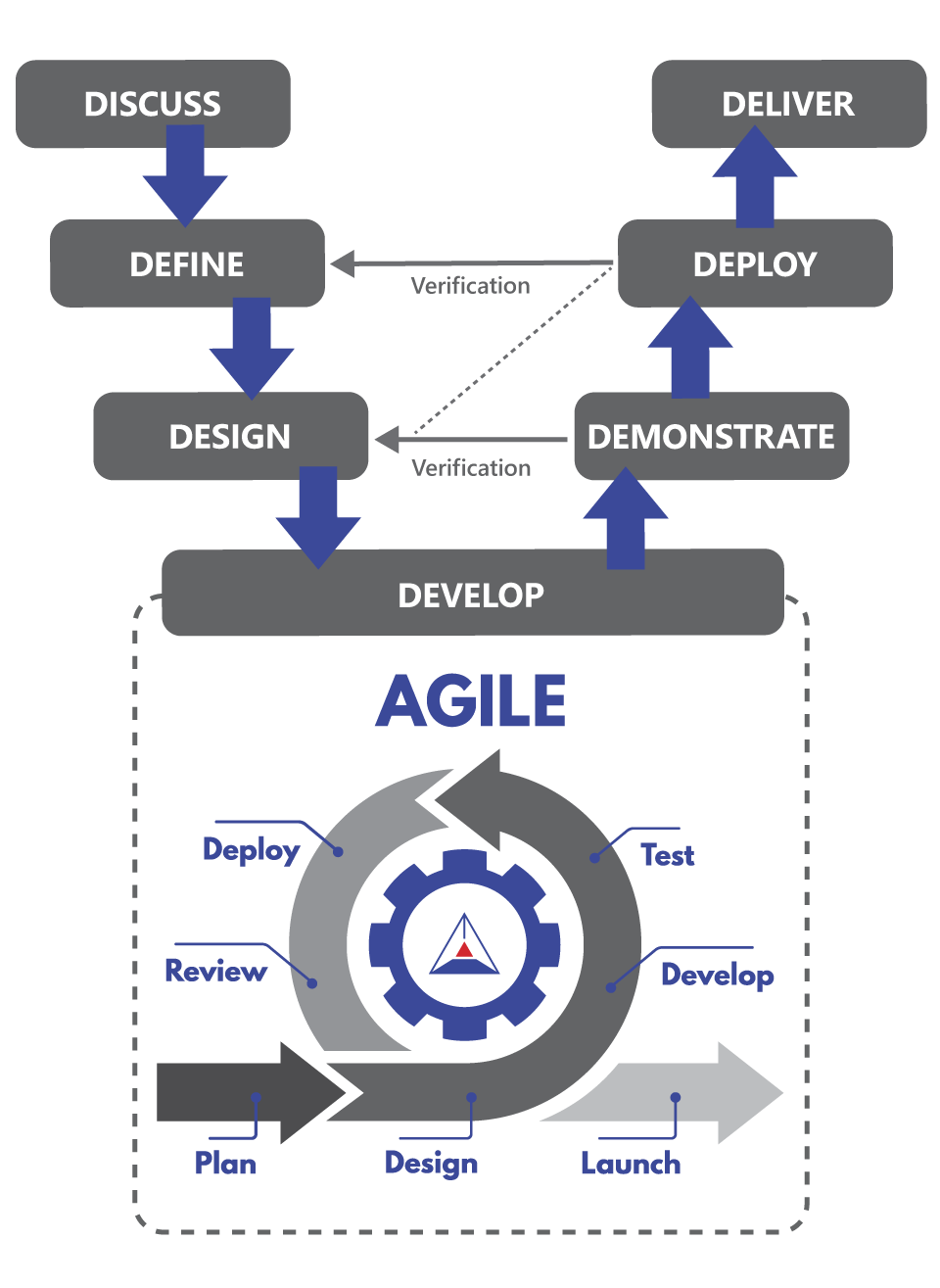

Cybertrol uses a customer-centric approach to implement projects. We engage with experts within our customers' facilities and partner design firms, leveraging our experience to create a unified plant operation.

User Requirement Specification (URS):

Cybertrol will engage in discussions with the customer to understand their primary pain points and collaboratively develop the user requirement specifications.

Deliverables:

Functional Description Specification (FDS):

In this phase, Cybertrol develops the functional definitions and creates the system and software architectural drawings. These are then reviewed with the customer and the design team.

Deliverables:

Software Design Specification (SDS):

In the design phase, detailed requirements are provided to the Cybertrol team. These requirements guide the development of the specific documents needed for the system build process.

Deliverables:

System Build:

Cybertrol employs the Agile methodology by clearly defining the criteria for "done" and utilizing an iterative development cycle. This approach ensures customer expectations are met and development time is reduced.

Deliverables:

Installation Qualification/SAT (IQ):

During the demonstrate phase, which occurs throughout the Agile development stage, a Software Acceptance Test (SAT) is conducted. This test runs through the entire process and reviews the panel builds before they are implemented at the plant.

Deliverables:

Operational Qualification/IO Testing and Functional Testing (OQ):

Cybertrol collaborates with the implementation team to conduct functional testing of all devices, run sequencing through the installed equipment without product, and perform trial operations. This ensures the system operates according to the design specifications.

Deliverables:

Performance Qualification (PQ):

This final stage involves production testing and validation of the system to ensure it meets performance standards before handing it over to the end user.

Deliverables:

Why early automation and OT decisions shape cost, schedule, and long-term performance in food and beverage capital projects Scope creep is one of the most common challenges in ...

Cybertrol Engineering is proud to be recognized once again as a System Integrator Giant, earning a place on the 2026 System Integrator Giants list published by WTWH Media, LLC. on ...

Automation Fair 2025 provided a strong platform to demonstrate how modern process automation and manufacturing information systems can work together to enable plantwide ...

EATS (The Equipment, Automation, and Technology Show) 2025 is North America’s only event representing the full food and beverage production industry, bringing together processors, ...

Cybertrol Engineering was proud to receive the 2024 Spirit of Excellence Award from Hormel Foods Corporation. This recognition celebrates business partners who demonstrate ...

Cybertrol Helps Manufacturers

About Cybertrol

Cybertrol delivers end-to-end industrial automation, OT systems, and information solutions, ensuring every component of your project works seamlessly to achieve the right outcome. Our in-house team of engineers collaborates to design innovative, effective solutions tailored to your organization’s toughest challenges. With a strategic approach and a focus on results, we provide the expertise you need to drive success.

Implement Plantwide Upgrades

Many organizations feel stuck with outdated systems that limit efficiency and growth. Cybertrol provides a seamless path forward with expert development and integration strategies, transforming your plant into a state-of-the-art facility. Whether you're modernizing equipment, upgrading software, or optimizing processes, we help you execute a migration plan with minimal disruption to daily operations.

Your 24/7 Support Partner for Ongoing Success

Cybertrol delivers plantwide managed services with around-the-clock monitoring, diagnostics, and expert support to keep your facility running at its best. Our team responds quickly, diagnoses issues efficiently, and provides the right subject matter experts for any situation. No matter your challenges or goals, we’re here as your trusted operations partner—ensuring reliability, efficiency, and peace of mind.

World-Class Solutions for Industrial Challenges

Cybertrol collaborates closely with you to design tailored solutions that meet your unique needs. No matter your objectives, we deliver a seamless, end-to-end system that optimizes performance and efficiency.