The success of every Cybertrol-led project is backed by a systematic approach from start to finish. We follow proven procedures and a clearly defined road map with every client to ensure seamless integration and results that are easily maintained and scaled. Each project follows a design process that includes:

- Detailed review and development of functional requirements

- Customer review and approval

- System module development

- Complete build, configuration, and programming

- Internal hardware and software testing

- Factory acceptance testing with clients

- System commissioning and site acceptance testing

This process aligned with our 24/7 ongoing support results in a modular, scalable, and seamlessly integrated system that’s easy for clients to operate and maintain, leading to a low cost of ownership and lasting ROI.

Decades of Engineering Innovation

For decades, Cybertrol has helped organizations improve the way they do business through plantwide integration and best-in-class engineering solutions. We've spent years developing and perfecting our process to provide each client with results that serve their needs and are designed to grow alongside their organization.

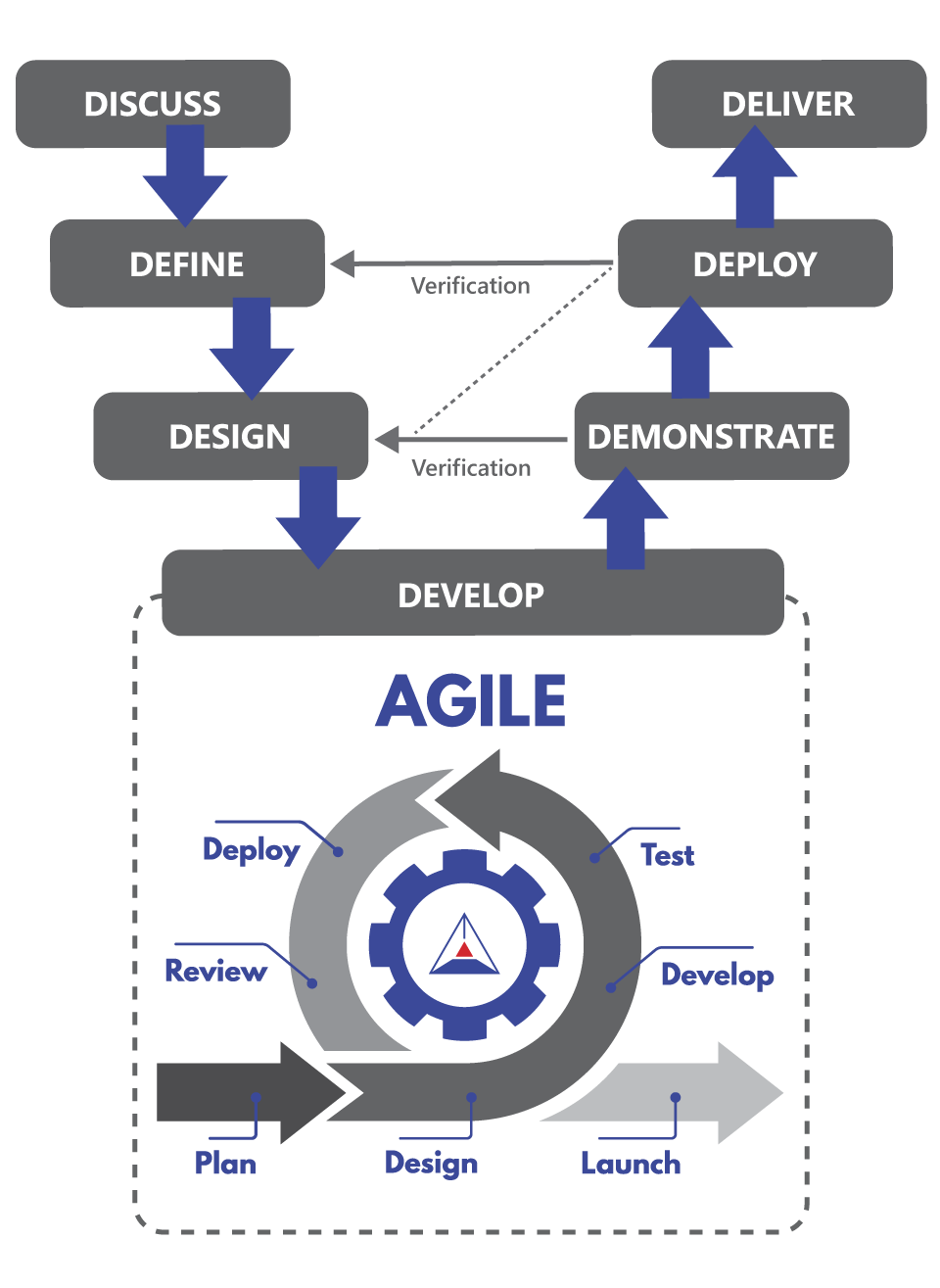

Cybertrol is set apart by our Agile engineering methodology, our proven process, our multi-discipline approach, and our start-to-finish project support. Our industry-leading simulation is closely aligned with customer needs to help achieve the right outcome during integration and after commissioning. We are dedicated problem solvers, skilled at integrating new and existing components with minimal disruption to your daily operations. Our expertise ensures that all project elements work together as a cohesive system, customized to function seamlessly within your facility.

The Cybertrol Difference

Our Proven Process

Cybertrol uses a customer-centric approach to implement projects. We engage with experts within our customers' facilities and partner design firms, leveraging our experience to create a unified plant operation.

DISCUSS

User Requirement Specifications:

Cybertrol will engage in discussions with the customer to understand their primary pain points and collaboratively develop the user requirement specifications.

Deliverables:

- Definition

DEFINE

Functional Definition:

In this phase, Cybertrol develops the functional definitions and creates the system and software architectural drawings. These are then reviewed with the customer and the design team.

Deliverables:

- Functional descriptions

- System architecture documents

DESIGN

Design Specifications:

In the design phase, detailed requirements are provided to the Cybertrol team. These requirements guide the development of the specific documents needed for the system build process.

Deliverables:

- Software design specifications

- Electrical drawings

DEVELOP

System Build:

Cybertrol employs the Agile methodology by clearly defining the criteria for "done" and utilizing an iterative development cycle. This approach ensures customer expectations are met and development time is reduced.

Deliverables:

- PLC programming

- HMI programming

- SCADA development

- Industrial control panels

DEMONSTRATE

Installation Qualification/SAT (IQ):

During the demonstrate phase, which occurs throughout the Agile development stage, a Software Acceptance Test (SAT) is conducted. This test runs through the entire process and reviews the panel builds before they are implemented at the plant.

Deliverables:

- Software verification

- Drawing verification

- PLC IO verification

- Hardware verification

- Network address verification

DEPLOY

Operational Qualification/IO Testing and Functional Testing (OQ):

Cybertrol collaborates with the implementation team to conduct functional testing of all devices, run sequencing through the installed equipment without product, and perform trial operations. This ensures the system operates according to the design specifications.

Deliverables:

- Function testing

- HMI – Screen, parameter, and security testing

- Alarm testing

- Report verification

- SCADA functionality verification

DELIVER

Performance Qualification (PQ):

This final stage involves production testing and validation of the system to ensure it meets performance standards before handing it over to the end user.

Deliverables:

- Final testing

- System hand over

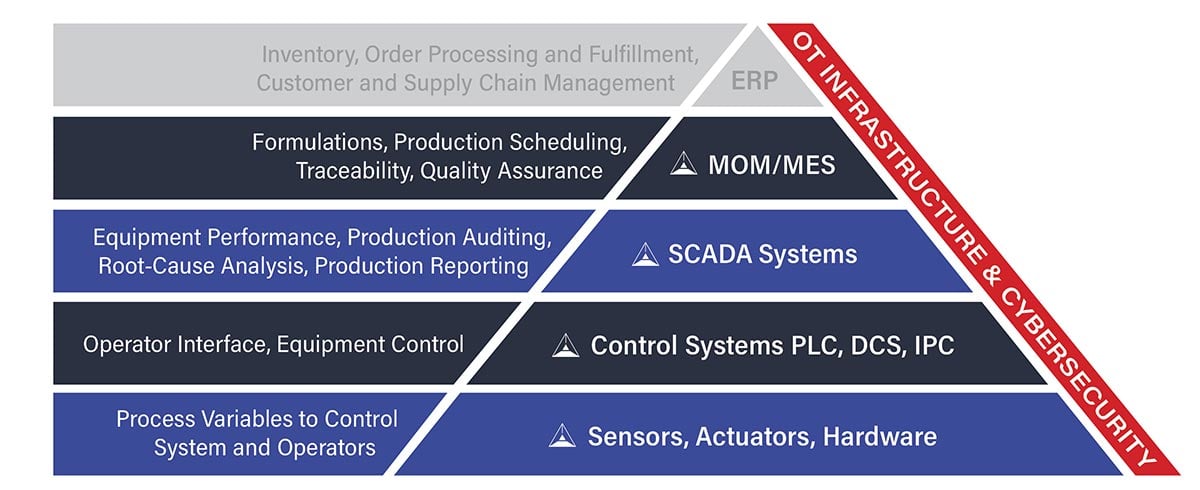

Shop Floor to Top Floor Capabilities

Cybertrol provides plantwide automation and information solutions that are engineered completely in-house by our multidisciplinary teams. We have staff engineers who are aligned with each layer of the ISA-95 Enterprise Control System Integration model—including dedicated teams for:

- Hardware specification

- Controls and SCADA programming

- Network and server infrastructure

- Software and business system integration

Each of these teams can be leveraged independently depending on the scope of your project—be it a stand-alone skidded system, a formalized manufacturing execution system (MES) installation, or a custom built-for-purpose software application.

Contact Cybertrol today for a modular, scalable, and seamlessly integrated system.

Contact Us