Modern, Enterprise-Wide Manufacturing Intelligence

Industrial Data Integration & Enterprise Reporting Platform for Manufacturing

Cybertrol’s Enterprise Reporting Platform connects plant‑floor data with enterprise systems to make manufacturing data usable at scale. By bridging operational technology and enterprise reporting tools, the platform delivers timely visibility, standardized reporting, and actionable insight across sites, processes, and roles.

Designed for multi‑site manufacturers, the platform supports both day‑to‑day operational awareness and long‑term performance analysis, all through secure, browser‑based access.

What the Platform Delivers

Enterprise-Wide Visibility

Establish a consistent, enterprise view of manufacturing performance across all locations. Standardized dashboards allow leadership teams to compare sites, identify trends, and understand where attention is needed without relying on spreadsheets or manually consolidated reports.Site Level Operational Insight

Plant teams gain access to site‑specific dashboards that surface current production status, key performance indicators, and process health. These views support faster response to issues, improved coordination between shifts, and clearer communication between operations and engineering.Batch and Process Reporting

For batch‑driven and process manufacturing environments, the platform provides detailed batch summaries, batch histories, and comparisons against predefined or “golden” batches. Users can investigate deviations, analyze process performance over time, and improve consistency across runs and sites.

Operational and Historical Data Access

Operational Technology (OT) data is collected directly from plant systems and made available for timely monitoring alongside long‑term historical analysis. This combination gives teams the context needed to understand what is happening now, why it happened, and how performance is trending over time.

Built for Industrial Data

The Enterprise Reporting Platform is designed to work with the realities of industrial environments and existing automation investments. It integrates with common manufacturing data sources, including:

- PLC and control system tag data

- Batch and MES platforms

- Existing SQL‑based data sources

- Industrial historians used for high‑resolution trending

Rather than replacing plant systems, the platform builds on them. Data is organized and contextualized into a consistent, enterprise‑ready model that supports reliable reporting across sites.

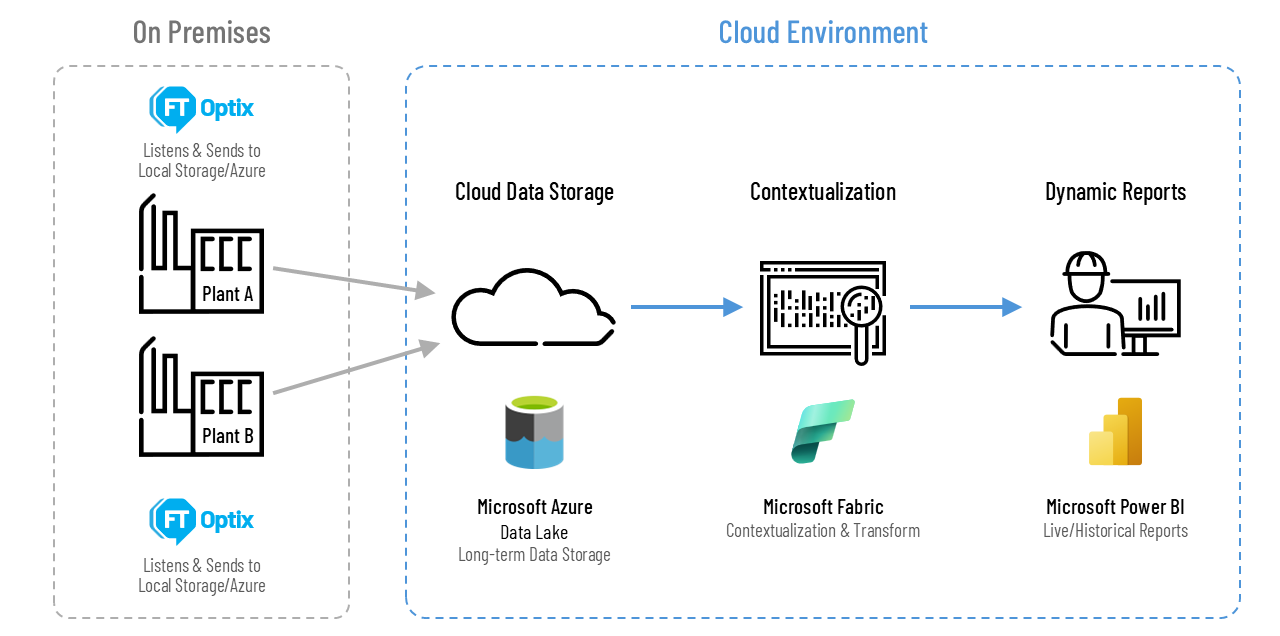

Cloud Enabled Architecture

At the core of the platform is a secure, cloud‑hosted architecture that supports scalability, governance, and enterprise access:

-

Centralized Cloud Data Lake – Operational data from multiple plants is ingested and stored in a centralized cloud data lake, creating a single source for enterprise reporting and analysis.

-

Data Contextualization – Raw OT data is transformed into business‑ready information that aligns with manufacturing processes, equipment, and production context.

-

Web‑Based Reporting – Interactive dashboards and reports are delivered through standard web browsers with appropriate authentication, allowing users to access information without specialized software.

This architecture supports enterprise reporting while maintaining appropriate separation between plant‑level control systems and business analytics.

Reporting Experiences for Every Role

Different users need different views of the same data. The Enterprise Reporting Platform supports multiple reporting experiences tailored to each audience:

-

Executive and Management Dashboards – High‑level KPIs, production summaries, and cross‑site comparisons that support strategic planning and performance review.

-

Operations and Engineering Views – Detailed process, equipment, and batch insights focused on troubleshooting, optimization, and continuous improvement.

-

Compliance and Historical Reporting – Structured historical data suitable for audits, quality analysis, and long‑term record retention.

The following example report screens represent preliminary mockups that illustrate the types of dashboards and visualizations that can be developed. Prior to formal development, Cybertrol will work collaboratively with project stakeholders to define the final look, feel, and functionality of each report.

Site Overview – A site-level view displaying the status and operating conditions of key process equipment. Additional equipment-specific reports can be enabled for select locations as automation is deployed. Other equipment at remaining sites can be added as those systems come online.

Equipment Overview – A detailed equipment report showing current production status. This view is designed to clearly display progress through each cycle, including a comparison of actual progress against anticipated progress or a predefined ideal or “golden” profile.

Batch Reports – Historical, detailed reporting that provides full visibility into batch activity across all sites. Reports can be filtered by site, batch ID, date range, or other selected criteria to support quality investigations, traceability, and operational analysis.

Configurable and Scalable by Design

Manufacturing environments evolve over time. The Enterprise Reporting Platform is designed to scale and adapt as needs change:

- Modular report design supports the addition of new assets, processes, or sites.

- Standardized data models promote consistent reporting across the enterprise.

- A flexible architecture enables future expansion into advanced analytics, machine learning, and ERP or business system integration.

Implementation Approach

Cybertrol follows a structured, customer‑centric approach to implementation:

-

Requirements Definition – Collaborative development of reporting requirements and visual mockups aligned with operational and business needs.

-

Architecture & Design – Secure, scalable system design aligned with IT and OT standards.

-

Development & Integration – Data collection, contextualization, and report development using proven manufacturing intelligence practices.

-

Validation & Review – Iterative review cycles to verify data accuracy, usability, and business value.

-

Deployment & Support – Transition to production with options for ongoing support and future enhancements.

Why Cybertrol

Cybertrol brings deep experience in industrial automation, operational technology, and manufacturing intelligence. By understanding both the plant floor and the enterprise, Cybertrol helps manufacturers turn production data into clear, reliable insight that supports better decisions at every level.

Cybertrol streamlines processes and provides real-time insights all in one place. Our solutions address performance management, production management, materials management, quality management, and more. We implement our manufacturing intelligence expertise to help decision-makers understand and optimize conditions on the plant floor to improve output across the board. Our solutions include:

- Performance-OEE

- Production Management

- Batch Management

- ERP Integration for: Inventory, Consumption, Work Order, BOM’s

- Traceability and Genealogy

- Quality and SPC

- Recipe Management

- Materials Management

- Workflow Management

- Reporting and Dashboards

View our brochure >>> Manufacturing Intelligence Solutions

Cybertrol defines and configures collection and reporting systems using proven software solutions, allowing us to address data ranging from automated shift reports and log sheets to operational dashboards and process data. We build reports and dashboards to display data within the context of the viewer, from management to maintenance and R&D.

Our team of experts develops a wide range of applications varying from custom hardware interfaces to complete manufacturing operating systems. Our solutions are capable of integrating multiple operator systems to central system database and application servers. We’ll work with you to determine your needs and to create an app that will optimize the way you operate.

Contact Cybertrol to learn how our Enterprise Reporting Platform can deliver clarity, consistency, and confidence across your operations

Contact Us