Enhance Batch Control Precision & Flexibility with BatchWorks

Cybertrol’s BatchWorks strengthens our batch control capabilities by building on extensive experience from numerous successful batch control projects across diverse industries. Our engineers, experts in the ISA-88 standard, leverage their knowledge to design optimal batch control systems tailored to your specific operational needs. With BatchWorks, we ensure precise recipe execution and seamless production scheduling, while offering flexibility in recipe editing, formulations, and system validation.

BatchWorks Integration Software by Cybertrol Engineering

Batching System Extensibility Including: Scheduling, Recipe and Formulation Management, Inventory Consumption, Quality Control, and Production Traceability

Cybertrol Engineering’s BatchWorks is web-based, purpose-built integration software that seamlessly transacts material consumption and production information with your MES or ERP system, enabling real-time visibility to production cost, inventory availability, batch cycle time, and batch quality.

The BatchWorks programming strategy utilizes the ISA88 batch control standard for design with phase-based recipes to support the operations of the batch process. From this environment, the supervisor/operator can create, copy, and modify recipes, run and phase automatic recipe execution, and manually adjust operations. Recipes can include operator prompts for assuring process connections are made, such as, adding hand-applied ingredients, acknowledging process steps (quality checks), etc.

Cybertrol Engineering's BatchWorks enhances recipe management and scheduling functions.

BatchWorks seamlessly integrates with server-based or PLC-based batching engines. Modules include:

Allows recipes to be edited and stored. Allows recipes to be released for production.

Keeps versions of all recipes.

Schedules production across processing units. Once the batch or campaign is scheduled, it is pushed to the controller, which will then display the current batch list on the HMI. The operator selects the desired batch to run and starts it. The system will run the batch per the downloaded batch recipe.

Executed batches will store batch records into a database.

Batch reports will be created to view the data.

Inventory consumption data transactions with MES or ERP after performing batch certification.

BatchWorks by Cybertrol Engineering – Connecting FactoryTalk Batch to the ERP System

BatchWorks is purpose-built integration software, developed by Cybertrol, that enhances Rockwell Automation's FactoryTalk Batch by integrating material consumption and production data with ERP systems. It supports FactoryTalk Batch, PlantPAx Logix Batch Sequence Manager (LBSM), and other ISA-88 solutions.

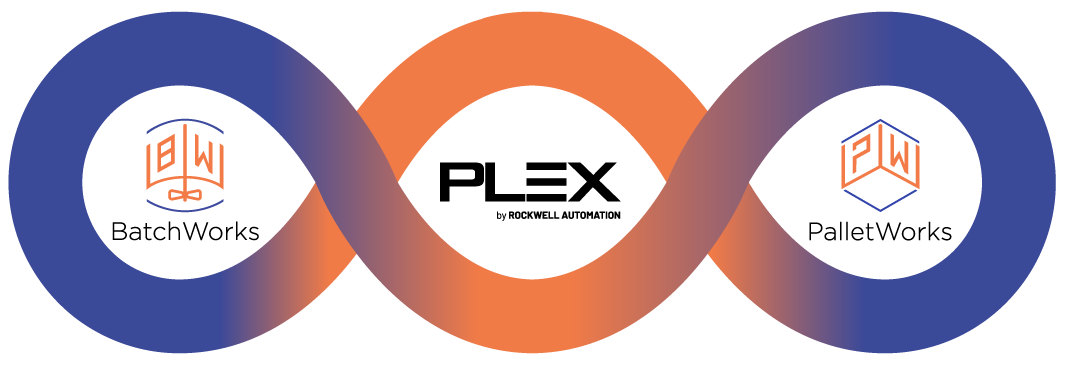

Unlock Complete Manufacturing Efficiency with Cybertrol's Integrated Solutions

Cybertrol Engineering is transforming manufacturing operations with our innovative software solutions—BatchWorks and PalletWorks—now seamlessly integrated with Rockwell Automation’s Plex MES. Together, they deliver a closed-loop manufacturing system that revolutionizes production processes. From scheduling and recipe management to label verification and end-to-end traceability, our integrated solutions provide unparalleled control and visibility across your operations.

Plex MES

BatchWorks Integration Software

FactoryTalk Batch

PalletWorks Production Labeling Software

BatchWorks Web Interface - Batch Status

Contact Cybertrol Engineering to enhance your batch process with BatchWorks integration software.

Contact Us